HVLS – High Volume Low-Speed Fans

HVLS fans are large-diameter, ceiling-mounted axial fans designed to circulate considerable volumes of air at low operational speeds. The number of blades used varies by design and manufacturers, but most manufacturers today use between three and eight blades.

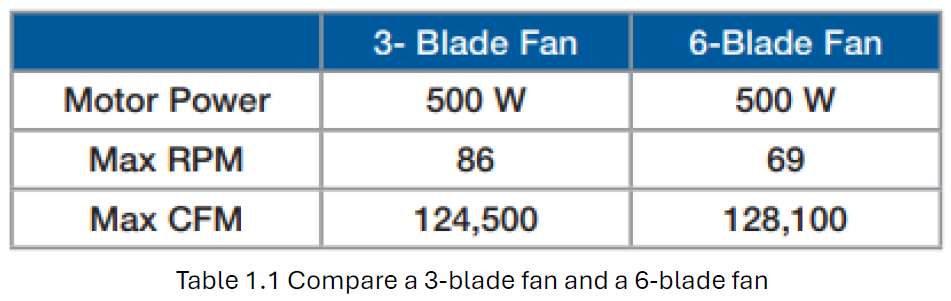

A common assumption among those unfamiliar with HVLS fans is that more blades create more air movement. Therefore, if three blades do a good job moving air, then six blades should work twice as well. Performance between a three and six-bladed fan when motor power is held constant (Table 1.1)

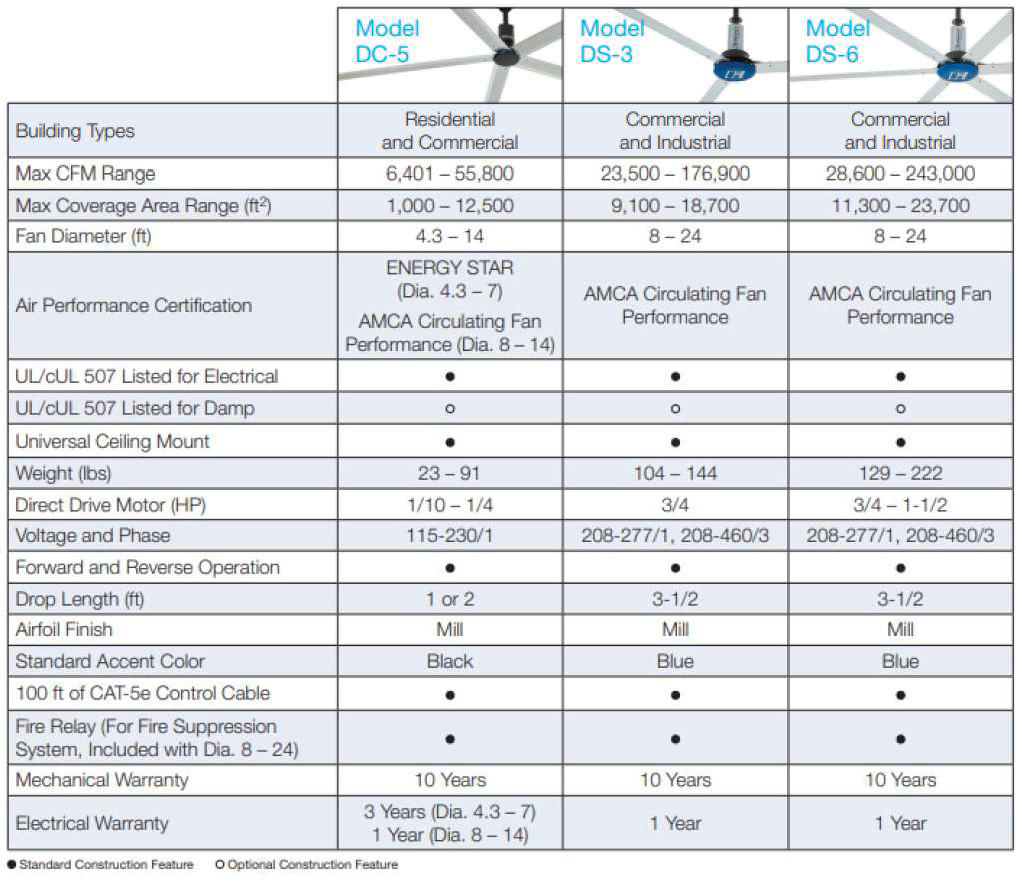

Why use HVLS fans of Greenheck?

- Energy Efficiency: HVLS fans provide substantial airflow while consuming less power compared to conventional fans, especially when using direct-drive motors over gearbox motors. This leads to significant energy savings.

- Thermal Comfort: HVLS fans help maintain uniform temperatures by destratifying the air, which improves comfort for occupants and helps meet ASHRAE 55 standards. This can result in increased productivity.

- Safety Improvements: By reducing condensation on floors and surfaces, these fans help mitigate the risks of slips, trips, and falls, leading to fewer workplace injuries and compensation claims.

- Cost-Effectiveness: A single HVLS fan can cover large areas (up to 23,000 square feet), reducing the need for multiple smaller fans. This reduces upfront costs and long-term maintenance needs.

- Low Maintenance: Direct drive motors, favored for their quiet and efficient operation, require less maintenance than traditional gearbox systems, which have moving parts like gears and bearings that demand regular upkeep.

- Noise Reduction: Direct-drive motors produce less noise compared to gearbox motors, making them suitable for environments where quiet operation is critical.

- Improved Aesthetics: HVLS fans are increasingly being incorporated into building designs for their visual appeal, reconfigurability, and customizable paint options.

Engineering Analysis

- Multiple Fan Systems: Enhancing Airflow Efficiency.

In air movement systems, multiple fans are sometimes used to optimize performance, efficiency, and control. This approach can be more effective than relying on a single large fan, particularly in complex or demanding environments.

Key Benefits of Multiple Fan Systems:

- Space and Weight Constraints.

- Enhanced Control.

- Redundancy and Safety.

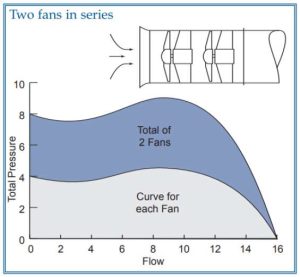

- Series Configuration: Fans in series are used when higher pressure is required. This setup allows each fan to handle part of the total system pressure, resulting in smoother operation and reduced noise.

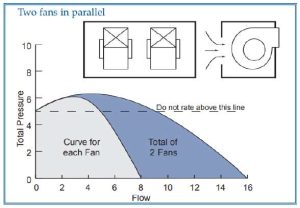

- Parallel Configuration: Fans in parallel are ideal for increasing airflow. This configuration distributes the total flow among multiple fans, helping to stabilize system performance.

- Maintenance and Downtime: Multiple fans improve system reliability by allowing one fan to be maintained or repaired while others continue to operate, minimizing downtime.

By understanding the design considerations and selecting the right configuration for your application, multiple fan systems can significantly enhance the efficiency, safety, and effectiveness of air movement solutions.

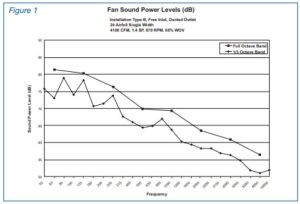

2. The Basics of Fan Sound

Understanding fan sound is crucial in fan selection and application, as sound is a byproduct of fan operation that can affect comfort and productivity. This guide covers essential concepts about fan sound, including how it’s generated, rated, and perceived.

What is Fan Sound?

Fan sound is the result of various aerodynamic and mechanical factors, such as vortex shedding, turbulence, and mechanical components like motors or bearings. The combination of these elements creates a sound spectrum recognizable as fan noise.

Sound Power vs. Sound Pressure

- Sound Power: The total sound energy produced by the fan, independent of environment and distance.

- Sound Pressure: The sound level experienced by listeners, influenced by the fan’s environment and distance from the source.

Measurement and Standards

Fan sound is measured in decibels (dB) across different octave bands, with standards like ANSI/AMCA ensuring consistent, reliable sound ratings. Sound levels can also be simplified into single-number ratings like dBA or sones for easier interpretation.

Understanding Loudness and Frequency

Loudness (amplitude) and pitch (frequency) determine how we perceive fan sound. Most fan sounds are concentrated between 50 Hz and 10,000 Hz, with differences in loudness and frequency affecting the overall acoustic experience.

Practical Applications

By considering fan sound ratings during the design and selection process, engineers and contractors can ensure that fans meet acceptable noise criteria for various environments, from industrial settings to residential spaces.